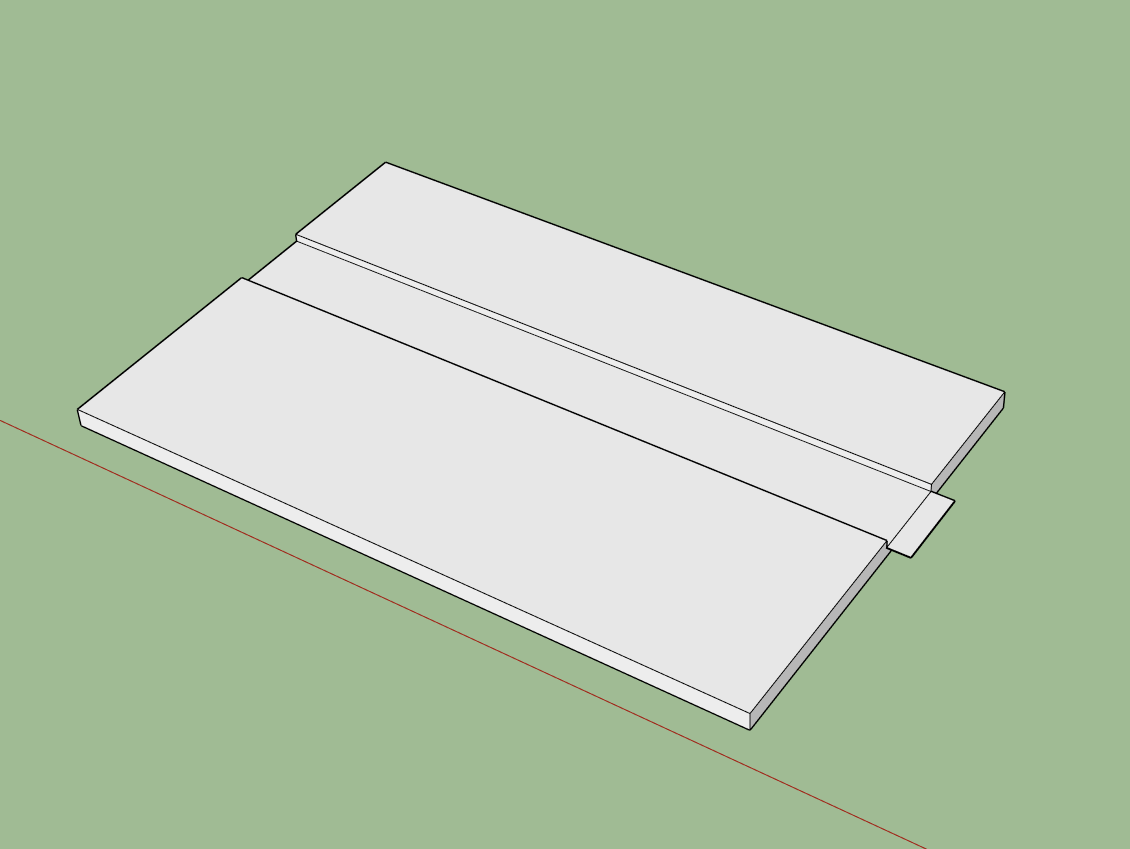

We have some designs with what I will call ‘trench pockets’. These are 9mm deep, into which we make a 90 degree butt joint. Sometimes these trench pockets can extend to the perimeter of any given cut profile.

Problem: Prior to Fabber (which is showing extreme promise in our workshop, I might add) we would extend the trench pocket beyond the cutting profile into the waste area of the material so we could make a nice 180 degree turn and continue back along the tool path within our profile. We do this, obviously, to avoid unnecessary radii within the bounds of our trench pocket etc.

I wonder, is there something I can work into the initial SketchUp design so the kind of tool path I describe above is output as such in the SVG file?