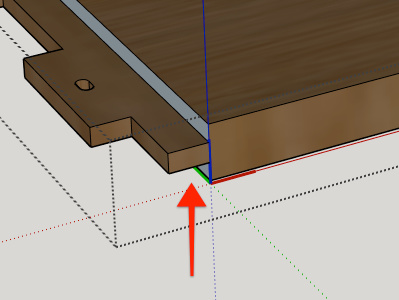

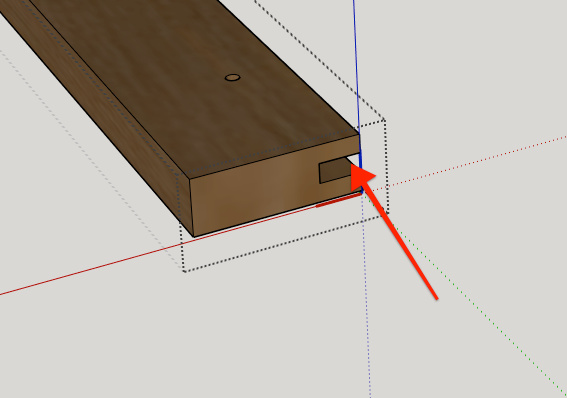

Plugin unsuccessful with components utilizing tenons. For instance, a table top with breadboard ends is current project. Highest elevation of the component is treated as cutout (sometimes, but in this case, it was deemed a pocket = 32"x64" table top ground away with a pocketing toolpath - yikes!).

Typically the tenons are considered a pocket, but no outline for cutout is generated, so they end up being cut off. Also, bottom of tenon, being offset upward, is considered another pocket, so it grinds away the tenon with yet another pocketing toolpath. Further complicating the matter is holes for pinning on the breadboard end. They too are considered 2 entities - one at the entry depth of the tenon, another at the exit point. I could simply discard erroneous pocket, but that still leaves node editing/copying vectors to cutout layer in order to re-gain the true profile, which includes tenon outline. Frankly, at 10+ years Sketchup user, I just have a frustrating time drawing /editing anything even mildly complex in VCPro. Node editing is bloody tedious for me. Seems only remedy may be to draw components in anticipation of how the plugin will interpret the item, meaning I must re-draw a dummy part strictly for machining(?).

Bottom line: I enjoy cleanliness of svg files - yes, arcs are now correct, and no tedious stitching of open vectors is needed, so exporting from Sketchup with this plugin is a good thing in many instances.

However, with Vectric, too much confusion on holes/rabbets/dados/cutouts to be useful. I’m spending more time fixing/stitching than if I’d stick with old methodology of importing one set of vectors at a time. In my limited experience, this plugin simply gets too confused by 2.5D objects for me to continue it’s use as a toolpath generating assistant.

Perhaps I’ve missed important points regarding this in other topics here?

Jeff