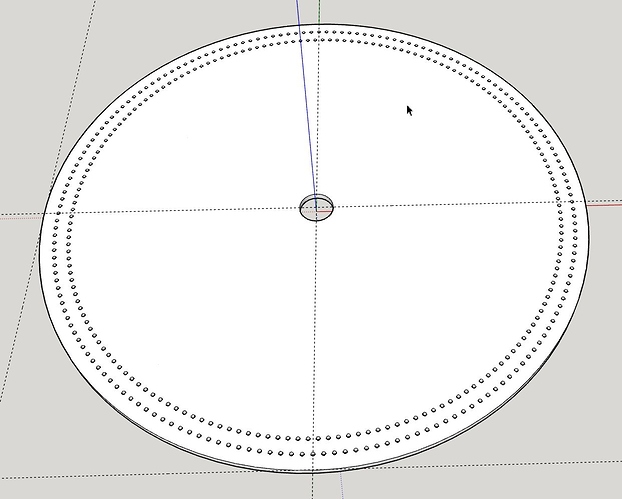

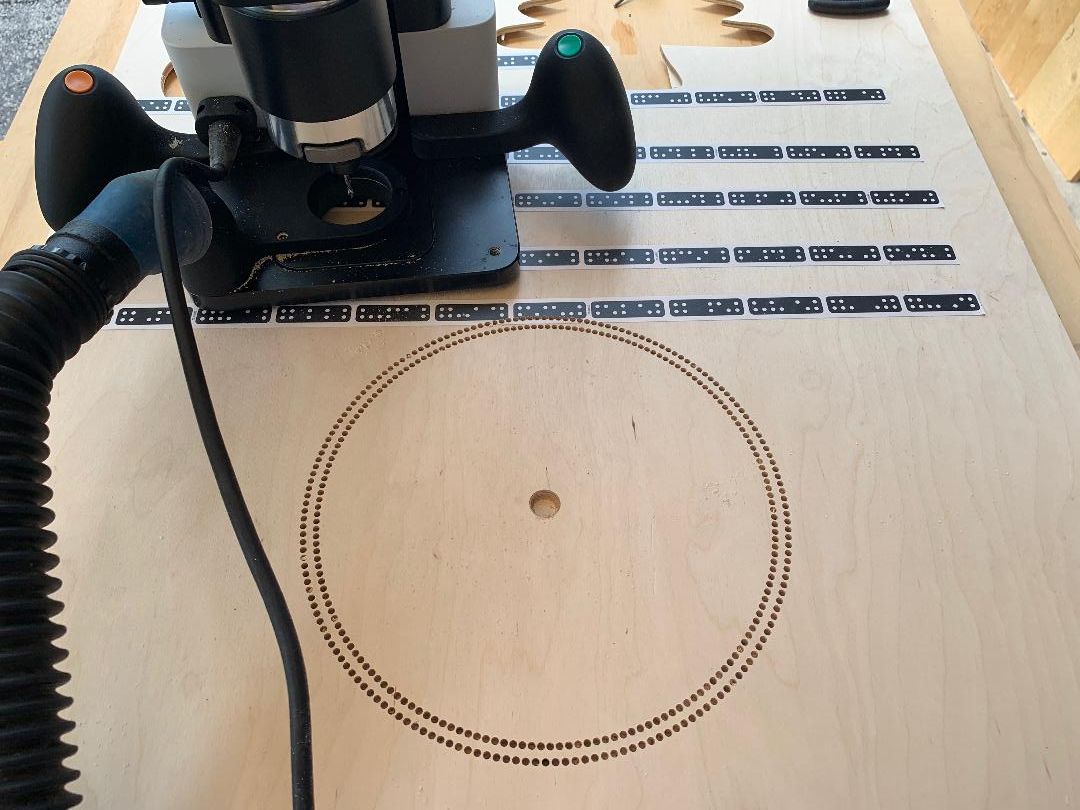

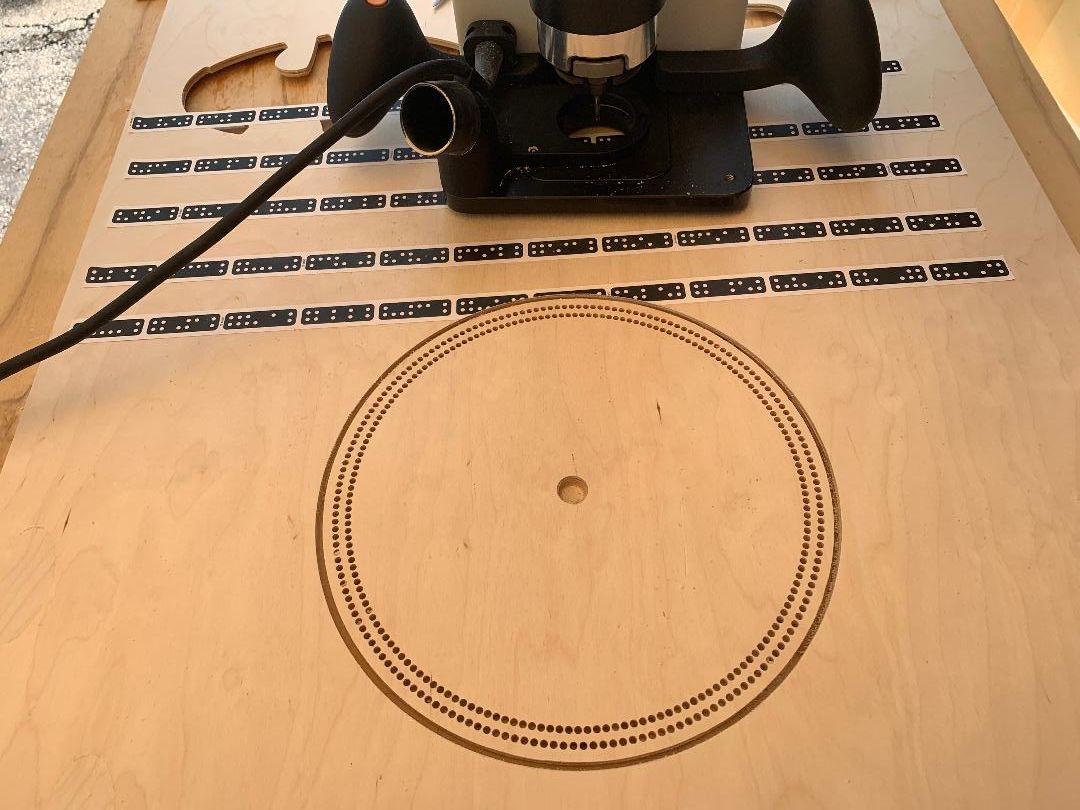

While the beta version was still working it was having issues with the project I was working on. It is a holey disk with 361 holes, the beta was taking a very long time trying to process it. I didn’t want to waste time on doing the whole project to only have it not work so I did much smaller version to play with. The beta version was taking a very long time to finish, I mean walking away and doing something else for a while and just coming back to check it… The new release with the performance improvements is amazing, really quick!

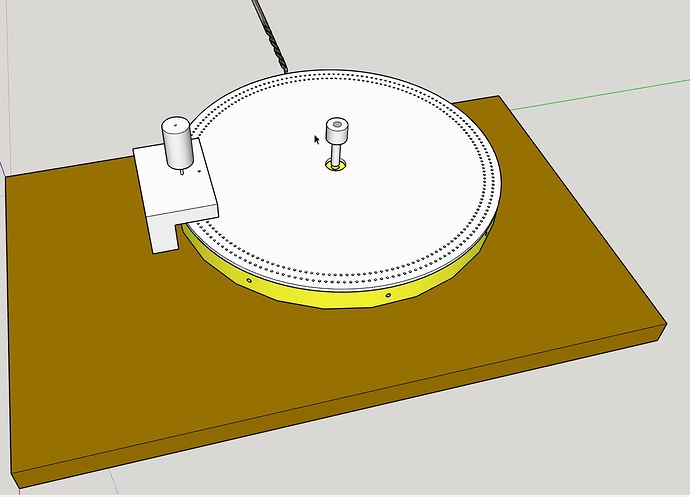

I will be making this with my Shaper but not sure when. I will be using some plastic for the disk, I hope something I have on hand. The disk will be 10" in diameter and have a hole at every degree around the outer edge. The smaller holes will be 1/16".

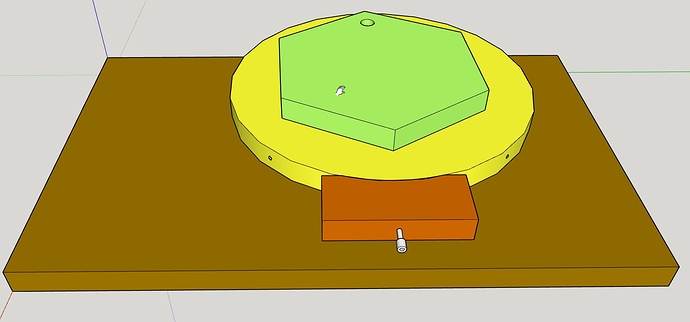

I will use this to make a drilling jig I’m working on. This one will allow any full degree patterns but of course not all patterns work that way so I might make another one for things like segments of 7, 11, 13, 14, 16, 17 and 19 or some sub set of those.

This might well be pushing what a Shaper is good for but it is what I have.

Ed