Had a couple hours today to do a full test after fiddling around last week with different parts of the total workflow. The plugin worked without issue and I think it could become my go-to, here’s why:

- I really like SU versus F360 for design, I have a pro license which gives me layout for drawings if I need them. The limiting factor pre-fabber was not having CAM.

- I need CAM because I have both the Shaper Origin and a Shapeoko 3.

- Using fabber I can design fully in SU and port out the svg for both SO and Shapeoko.

- I used makercam to create the g-code for Shapeoko from the svg.

- Some parts are best made with the Shapeoko (<400mm dimensions and intricate), while others that are outside its work envelope are better made with the SO (slots in a larger piece of ply).

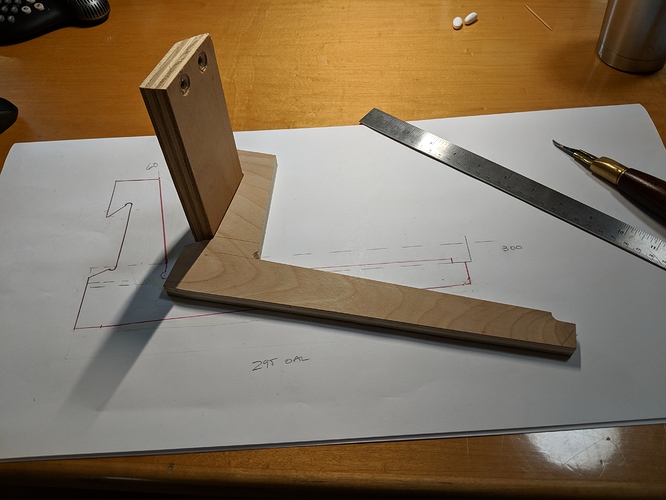

My project today included both, I made some french cleat brackets from 12mm ply and next I need to cut a corresponding dado/slot in the bottom of the shelves for the brackets to lock into. Here’s the bracket:

The shelves will have a stopped dado 6mm deep to capture the bracket with a full depth dado slot at the rear that will slip around the bracket and under the cleat to lock everything in place. I’ll post again when I get them done.

@Eric - kudos on the great work and a feature suggestion: add an option to preserve nesting in the svg export. Currently the plugin lines everything up if there are multiple components exported at once so in the makercam workflow I needed to nest everything. It’ud be great to be able to nest in SU and avoid having to do it in makercam, more precise.

If anyone knows of a better CAM generator than makercam I’d love to hear about it.

Thanks!

RMW

PS - the Festool sander in the first photo is perfect for getting into dogbones to clean them up.